Finding the Perfect Energy Solution for You

With our help, you'll have access to an energy system that's not only efficient and affordable, but also perfectly tailored to your specific needs and preferences.

Structural Design

Robust and Reliable Frameworks

EMS & BMS

Smart Energy & Battery Management Solutions

Solar MPPT

Maximize Solar Power Efficiency

Leading the Way in Customized Energy Solutions

Tailored energy solutions for maximum efficiency, sustainability, and cost-effectiveness.

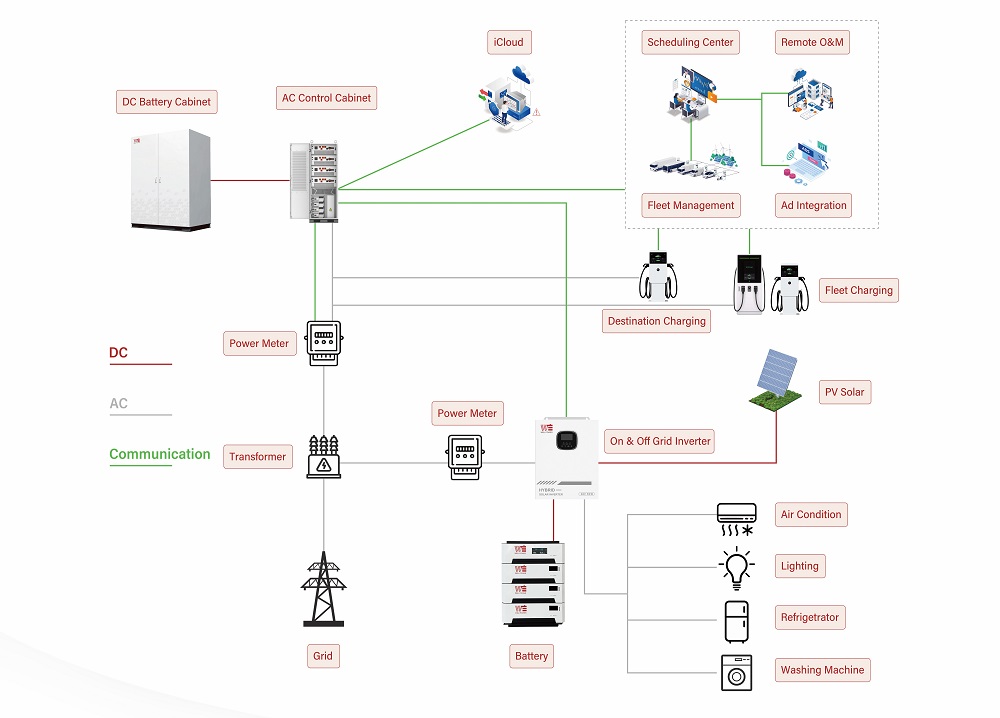

Our solutions are designed to seamlessly integrate charging piles and battery energy storage, optimizing energy efficiency and reducing reliance on the grid.

Our team can design and configure a system that includes the battery cabinet and AC control cabinet, as well as an Energy Management System (EMS) to optimize energy efficiency and reduce costs.

We offer professional solutions that include battery modules, solar inverters, and solar panels to meet your specific needs. Customized system solutions or component packages both are available.

LOCAL EPC TEAMS IN EUROPE

Having THREE local teams in Europe for local installation and after-sales service allows us to provide prompt and efficient support to our customers, tailored to your unique needs and ensuring your satisfaction.

Croatia

Sweden

Poland

What is EPC?

EPC stands for Engineering, Procurement, and Construction. It is a type of contracting arrangement commonly used in large-scale infrastructure and construction projects, particularly in the energy and power sectors.

How To Get Your Unique Solution?

Requirements

Desired capacity, voltage, energy, and physical dimensions of the battery energy storage system, as well as any other specifications that you may have.

Structural Design

Selecting appropriate cells, designing the structure of the system, and developing software and a BMS with advanced control and management of the system.

Software Design

Design the software that controls the energy storage system, including the charging and discharging algorithms, communication protocols, and any other specific features required.

BMS

Design and integrate a BMS that monitors the battery pack's state, manages the battery pack's charge and discharge process, and provides communication functions.

EMS

Involves the assembly of electronic components and printed circuit boards, as well as testing and quality control measures to produce finished electronic products for distribution.

Manufacturing

Assembling and integrating battery cells, electronics, and control systems, as well as conducting testing to ensure the reliability and performance of the product.

Quality Control

Conduct quality control checks throughout the manufacturing process, including testing the functionality and safety of each battery pack before it is shipped to the customer.

Ongoing Support

Monitoring the system's performance, providing regular maintenance and upgrades, and conducting any necessary repairs. Additionally, Training services are necessary.

Real-World Success Stories

400kWh@200kW ESS

The energy storage system is in Shenzhen, Guangdong Province, with 400kWh of battery capacity and 200kWh of AC output.

480kW Charging Station

A 480kW charging station in Sweden is a high-powered electric vehicle charging station that can provide rapid recharging to EVs with high-capacity batteries.

Rooftop Solar Installation

250kW PV Inverter

Grid Solar System

- Accelerate your business

How Can Our Custom Solutions Address the Technical Barriers to Energy Storage Systems?

Compatibility Issues

Our energy storage systems are designed to be compatible with a range of energy sources and applications, allowing for seamless integration with existing infrastructure.

Safety Concerns

We prioritize safety in every aspect of our energy storage systems, including rigorous testing, monitoring, and maintenance protocols, to ensure that they meet the highest safety standards.

Cost Considerations

We offer cost-effective energy storage solutions that provide maximum efficiency and value, including financing options to make adoption more affordable for businesses and individuals.

Technical Complexity

Our energy storage systems are designed to be user-friendly and easy to operate, with intuitive interfaces and software that simplifies setup, monitoring, and management.

Performance Considerations

We use the latest technology and highest quality materials to ensure that our energy storage systems deliver optimal performance and durability, with a focus on efficiency and reliability that helps maximize return on investment.

UNIQUE Customized Design and Manufacturing Services

Our Customized Design and Manufacturing Services offer a unique approach that tailors solutions to each client’s specific needs, unlike traditional manufacturing methods that rely on standardized designs.

Traditional

Manufacturing

Traditional manufacturing involves mass production of physical products using assembly lines.

- Mass production

- Assembly lines

- Standardization

- Identical products

- Fast turnaround

- Consistent quality

- Lower costs

- Economies of scale

Traditional

Customization

Traditional customization involves manual adjustments to pre-existing products or designs.

- Manual adjustments

- Manual modifications

- Flexibility

- Similar products

- Moderate turnaround

- Variable quality

- Moderate costs

- Customer satisfaction

WELI's Customized Design and Manufacturing Services

Our Services are tailored to meet the specific needs of our clients with them a unique and personalized approach.

- Tailored solutions

- Collaborative development

- Customization

- Unique products

- Custom turnaround

- Tailored quality

- Custom costs

- Competitive advantage